Essential Skills for Modern Manufacturing Careers

The manufacturing industry has evolved dramatically with technological advances, creating new opportunities for skilled professionals. Modern manufacturing careers require a blend of traditional engineering knowledge and cutting-edge technical expertise. Whether you're entering the field as a machine operator, pursuing mechanical technical jobs, or seeking manufacturing technician support roles, understanding the essential skills can significantly impact your career trajectory and earning potential.

Core Technical Competencies in Manufacturing

Modern manufacturing environments demand proficiency in computer-aided design (CAD) software, programmable logic controllers (PLCs), and automated systems management. Professionals must understand lean manufacturing principles, quality control processes, and safety protocols. Knowledge of materials science, thermodynamics, and mechanical systems remains fundamental, while digital literacy has become equally important for equipment monitoring and data analysis.

Machine Operator Skills for Today’s Factories

Machine operators in contemporary manufacturing facilities work with sophisticated equipment requiring specialized training. Essential skills include understanding computer numerical control (CNC) programming, robotic system operation, and predictive maintenance techniques. Operators must interpret technical drawings, perform quality inspections, and troubleshoot equipment malfunctions. Problem-solving abilities and attention to detail are crucial for maintaining production efficiency and product quality standards.

Manufacturing Technician Support Responsibilities

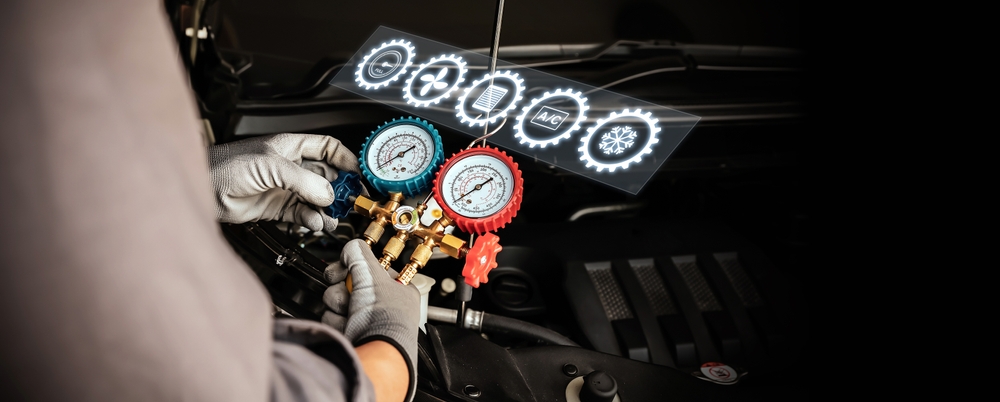

Manufacturing technician support roles encompass equipment maintenance, process optimization, and technical assistance across production lines. These positions require knowledge of hydraulic and pneumatic systems, electrical troubleshooting, and mechanical repair procedures. Technicians often serve as liaisons between engineering teams and production staff, requiring strong communication skills and the ability to document processes clearly. Understanding statistical process control and continuous improvement methodologies enhances career advancement opportunities.

Emerging Technologies Reshaping Manufacturing

Industry 4.0 technologies are transforming manufacturing operations through Internet of Things (IoT) integration, artificial intelligence, and advanced analytics. Professionals must adapt to smart factory environments where machines communicate autonomously and data drives decision-making. Familiarity with additive manufacturing, digital twins, and augmented reality applications provides competitive advantages in the evolving job market.

Educational Pathways and Certification Requirements

Manufacturing careers typically require technical education ranging from certificate programs to engineering degrees. Community colleges offer specialized training in manufacturing technology, while universities provide comprehensive mechanical engineering programs. Industry certifications from organizations like the Society of Manufacturing Engineers (SME) or National Institute for Metalworking Skills (NIMS) validate technical competencies and enhance employment prospects.

| Position Type | Required Education | Average Salary Range | Key Certifications |

|---|---|---|---|

| Machine Operator | High School + Training | $35,000 - $55,000 | NIMS Machining Level I |

| Manufacturing Technician | Associate Degree | $45,000 - $70,000 | SME Certified Manufacturing Technologist |

| Mechanical Engineer | Bachelor’s Degree | $65,000 - $95,000 | Professional Engineer License |

| Process Engineer | Bachelor’s Degree | $70,000 - $105,000 | Six Sigma Certification |

Salary ranges, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

Professional Development and Career Advancement

Continuous learning remains essential for manufacturing career success. Professionals should pursue ongoing training in emerging technologies, attend industry conferences, and participate in professional organizations. Cross-functional experience in different manufacturing processes broadens skill sets and increases versatility. Leadership development and project management capabilities open pathways to supervisory and management positions within manufacturing organizations.

Future Outlook for Manufacturing Careers

The manufacturing sector continues evolving with reshoring initiatives, sustainability requirements, and technological innovations creating new opportunities. Professionals with adaptable skill sets and commitment to lifelong learning will find abundant career prospects. The integration of traditional manufacturing knowledge with digital competencies positions individuals for success in an increasingly automated and data-driven industry landscape.